一、产品概述

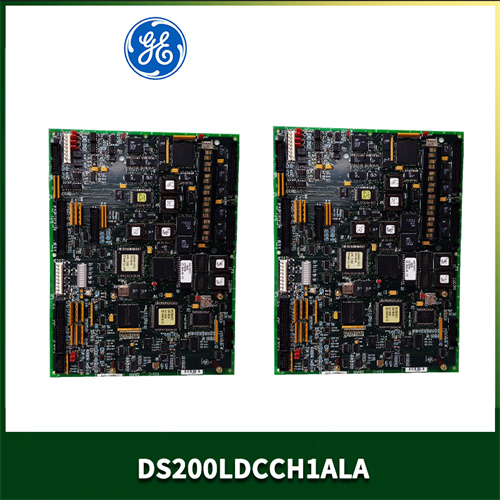

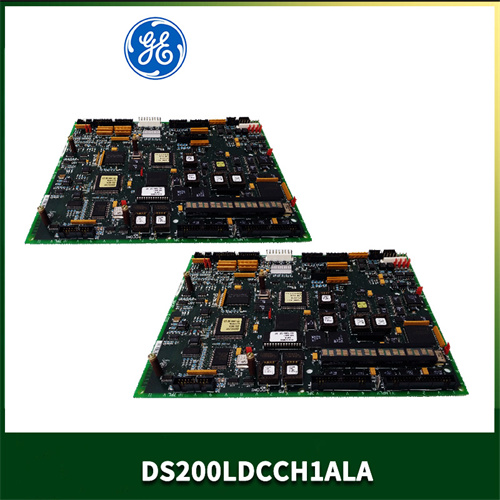

GE-DS200LDCCH1ALA是通用电气(GE)为Mark V系列控制系统设计的驱动控制与局域网(LAN)通信卡,专为工业自动化、电力设备控制、燃气轮机驱动等场景优化。该模块集成了驱动控制处理器(DCP)、LAN控制处理器(LCP)、电机控制处理器(MCP)和协同电机处理器(CMP),支持高精度运动控制与实时数据通信,广泛应用于DIRECTO-MATIC 2000系列驱动器及其集成系统中。

二、技术参数与核心功能

硬件架构

处理器配置:

DCP:处理数字/模拟I/O信号,支持电机控制指令;

LCP:管理LAN通信协议(如MODBUS、EtherNet/IP);

MCP:执行基础电机控制逻辑;

CMP:补充MCP的高复杂度计算需求。

通信接口:

1个以太网端口(支持LAN通信);

多路数字/模拟I/O接口(支持电压、电流、热电阻信号输入)。

电源与功耗:

工作电压:18.5~36 VDC;

功耗:≤5 W(典型值)。

电气特性

环境适应性:

工作温度:-5°C~+55°C;

环境湿度:0%~95%(非冷凝);

防护等级:IP20(控制室安装)。

机械参数:

重量:1.29 kg;

外形尺寸:35 mm(模块式设计)。

功能扩展

模拟量输入:支持8通道(电压/电流/热电阻),可配置16位整型或32位浮点数据输出;

数字量控制:集成逻辑运算与脉冲信号生成,支持电机启停、方向切换等操作;

LAN通信:通过以太网实现远程监控、参数配置及故障诊断。

三、典型应用场景

工业自动化控制

电机驱动:控制风机、泵阀、传送带等设备的转速与位置,优化能源效率;

PLC系统集成:与GE Mark V控制器协同工作,实现复杂逻辑控制。

能源与电力系统

燃气轮机控制:作为燃机调速、燃料管理的核心模块,保障高可靠性;

变频器系统:集成于DC2000/AC2000变频器,支持多电机同步控制。

过程控制与智能制造

化工/石化行业:控制泵、阀门等设备的流量与压力,确保工艺稳定性;

智能工厂:通过LAN通信实现设备状态实时反馈与远程维护。

四、安装与维护指南

物理安装

机箱适配:兼容GE Mark V系列控制柜,支持控制室或现场安装;

接线规范:使用屏蔽电缆连接电源与通信接口,避免电磁干扰。

配置与调试

软件工具:通过GE Fanuc编程工具(如QuickPanel)配置I/O通道与通信参数;

参数标定:利用模块内置的标度变换功能,将模拟信号转换为工程单位。

维护建议

定期检查:清理散热通道,检测电源线连接可靠性;

故障排查:

LED指示灯:红色表示电源异常,绿色表示正常运行;

通信状态:通过以太网端口检查数据包传输延迟。

1.Product Overview

GE-DS200LDCCH1ALA is a drive control and local area network(LAN)communication card designed by General Electric for Mark V series control systems,and is optimized for industrial automation,power equipment control,gas turbine driving and other scenarios.This module integrates a drive control processor(DCP),a LAN control processor(LCP),a motor control processor(MCP)and a collaborative motor processor(CMP),supports high-precision motion control and real-time data communication,and is widely used in DIRECTO-MATIC 2000 series drivers and their integrated systems.

2.Technical parameters and core functions

Hardware architecture

Processor configuration:

DCP:Process digital/analog I/O signals and supports motor control instructions;

LCP:manages LAN communication protocols(such as MODBUS,EtherNet/IP);

MCP:Execute basic motor control logic;

CMP:Supplementing the high-complexity computing requirements of MCP.

Communication interface:

1 Ethernet port(supports LAN communication);

Multi-channel digital/analog I/O interface(supports voltage,current,thermal resistance signal input).

Power and power consumption:

Working voltage:18.5~36 VDC;

Power consumption:≤5 W(typical).

Electrical characteristics

Environmental adaptability:

Operating temperature:-5°C~+55°C;

Ambient humidity:0%to 95%(non-condensing);

Protection level:IP20(control room installation).

Mechanical parameters:

Weight:1.29 kg;

Dimensions:35 mm(modular design).

Functional extension

Analog input:supports 8 channels(voltage/current/thermal resistance),can be configured with 16-bit integer or 32-bit floating point data output;

Digital control:integrated logic operations and pulse signal generation,supporting motor start-stop,direction switching and other operations;

LAN communication:Remote monitoring,parameter configuration and fault diagnosis are realized through Ethernet.

3.Typical application scenarios

Industrial automation control

Motor drive:controls the speed and position of fans,pumps,valves,conveyor belts and other equipment to optimize energy efficiency;

PLC system integration:Works in conjunction with GE Mark V controller to achieve complex logic control.

Energy and power systems

Gas turbine control:As the core module of gas turbine speed regulation and fuel management,it ensures high reliability;

Inverter system:integrated into DC2000/AC2000 inverter,supports multi-motor synchronization control.

Process control and intelligent manufacturing

Chemical/petrochemical industry:control the flow and pressure of pumps,valves and other equipment to ensure process stability;

Smart factory:Real-time feedback and remote maintenance of device status through LAN communication.

4.Installation and maintenance guide

Physical installation

Chassis adaptation:compatible with GE Mark V series control cabinets,supports control room or on-site installation;

Wiring specification:Use shielded cables to connect the power supply and communication interface to avoid electromagnetic interference.

Configuration and debugging

Software tools:Configure I/O channels and communication parameters through GE Fanuc programming tools(such as QuickPanel);

Parameter calibration:Use the built-in scale conversion function of the module to convert analog signals into engineering units.

Maintenance recommendations

Regular inspection:Clean the heat dissipation channel and check the reliability of the power cable connection;

Troubleshooting:

LED indicator:Red indicates abnormal power supply,green indicates normal operation;

Communication status:Check packet transmission delay through Ethernet port.